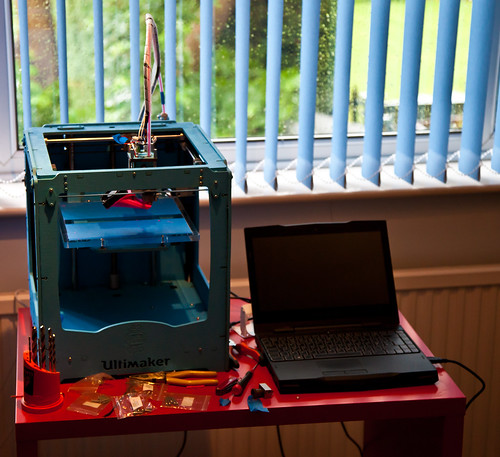

A gadget that makes gadgets is probably the ultimate gadget. So a few weeks ago I sold a whole bunch more cameras (I seem to do all my saving by means of the “camera bank”.) and ordered an Ultimaker. Peter reckoned that this was the best of the 3D printers and I was attracted to it by the level of detail that you could print with, and the fact that it came in a kit, which I could spend the upcoming bank holiday working on with Number One Son.

Several weeks later a heavy box arrived which contained motors, circuits and some lovely laser cut birch plywood which would be fitted together to make the finished printer. So, armed with the very detailed instructions and beautifully packaged and labelled pieces we set to work.

It was great fun. Like Lego, but bigger and with bits that light up, bits that get hot and bits that move. And you learn lots of new terms like “Bowden Tube”, “Peek insulator” and “STL file”. And at the end of it you have a thing that makes things. The principle is very simple. At one end you push a plastic fibre which goes down a tube to the “extruder head” which contains a heater and a very fine nozzle.

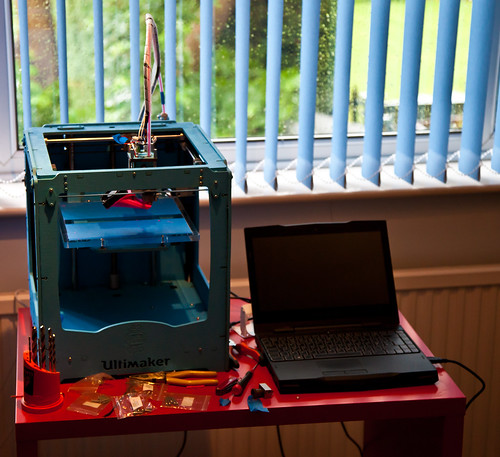

This is the finished product, I painted it blue. The machine “prints” in 3D by moving the head over a build surface, adding successive layers of extruded plastic to create the design you fed into it. It is fascinating to watch the head buzzing around. Number one son made a video of it printing out a Companion Cube here.

One of the great things about the printer is that it can print extra bits for itself. If you look at the picture above you can see a bright pink fan ducting on the print head which I printed and then fitted to replace the one that the printer ships with. The new duct does a better job of focusing the cool air onto the print so that it hardens more quickly. If I have an idea for a better design I’ll simply print that out and then fit it.

Tonight I decided to print out a new locking assembly for the “Bowden Tube”. This is the tube that guides the raw plastic fibre into the extruder head. I was especially interested in this because it contains a screw thread, and I wanted to see how this would turn out. The print did not go well, mainly because I left the printer heated for too long, and some fibre in the tube melted and formed a plug that stopped the flow. I had to strip down the print head, clean out the blockage and then rebuild everything. Two hours of messing around with bits and bobs. And I loved it. At the moment it is extruding very well, but I’ve got a little leak of plastic around the nozzle which I’ll have to seal up. I’m looking forward to adding some sealant and then trying again.

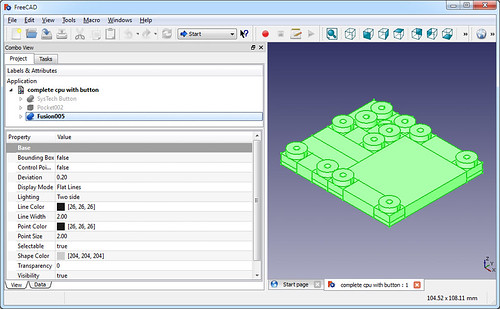

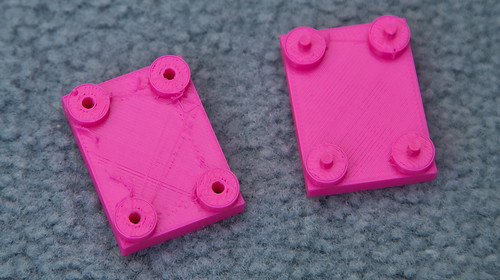

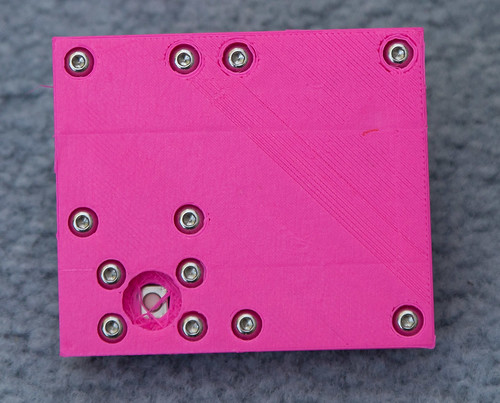

This is the assembly I printed tonight, with a knurled nut on top of the fitting and a thread that works really well. Perhaps I should get some different coloured plastic to work with…

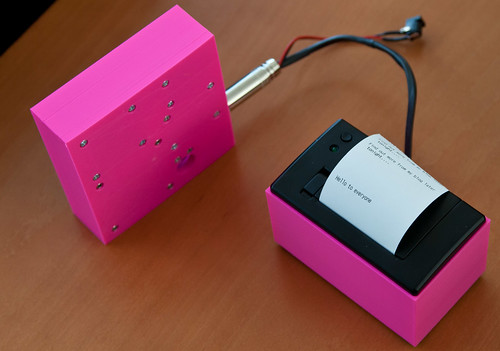

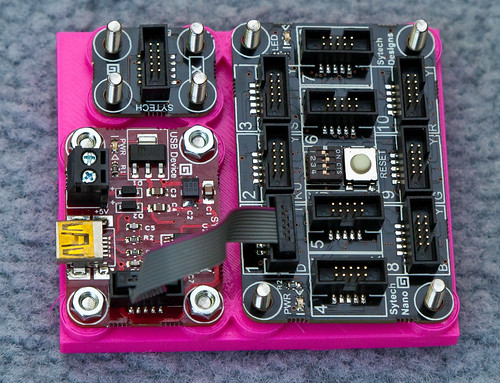

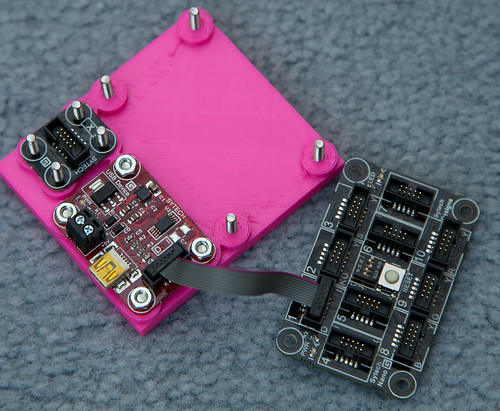

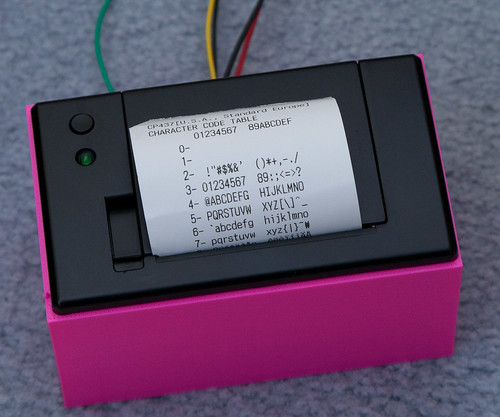

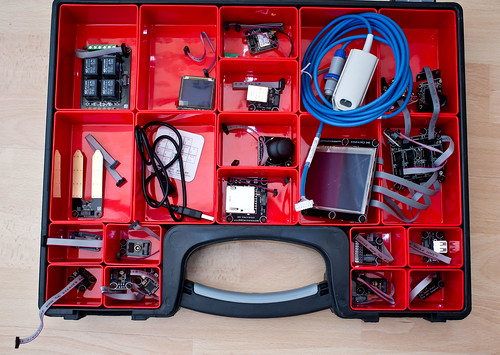

The main reason I got my Ultimaker was not to print parts for it (which would be kind of recursive) but to make cases for other gadgets. The Gadgeteer platform provides a lovely way of making devices, but they will still need a box. As long as the box is smaller than 8 inches in any direction (the build volume of the Ulitimaker) I can design and print it. We already managed to print out a box for number one son’s Raspberry Pie device.

This is not a technology ready for prime time. But it is a tinkerers delight. You don’t just get to play with the bits, you get to make more bits to play with too. There might be people out there who will say that in the future everyone will have an Ultimaker, and that one day the machines will make themselves. This might happen at some point, but great as it is I can’t see my little blue box printing out a Stepper Motor or a Microcontroller any time soon. To me it is very similar to the very first TVs that were made by John Logie Baird. They worked by spinning disks and flashing lights and were thoroughly impractical for proper viewing. But they got people engaged with the idea of being able to view things over long distances. The Ultimaker is just like this. It is slow (although really fast for a 3D printer), noisy and not 100% reliable, but that doesn’t matter. What it does seems as magical as watching someone 100 miles away must have seemed in 1925. When people really figure out how to do this, how to make different colours and build more quickly, then I can see that there really will be one in every household. And another piece of Star Trek technology will have arrived in our lives.

We will be launching a spin off from Three Thing Game (Three Thing Thing) later this year when we will get people building gadgets using Gadgeteer (keep your diaries clear for the 27th – 28th of October folks) and I’ll bring along the printer so that we can make some boxes for whatever gets made.

Oh, and if you want to find out more about Gadgeteer, Peter has produced some superb posts about the platform.