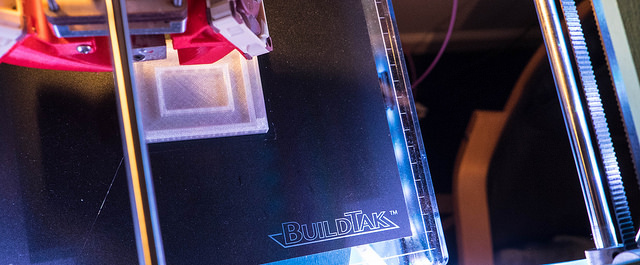

BuildTak Printer Surface

/While I was at the 3D printer show a while back I picked up a sheet of BuildTak to put on Una, my Ultimaker printer. Up until now I've used 3M blue masking tape underneath all my prints, and it works quite well, but I've never been able to get a smooth finish because of the gaps between rows of the tape.

The surface that you print on is actually quite crucial, in that the heated plastic must stick to it well enough to allow the item to be printed but not so well that you can't get the darned thing off the bed afterwards.

BuildTak manages to do this very well. If you're like me, and you've not got a printed bed for your printer, then you might like to have a play. I'm much happier with the quality of the surfaces that I've printed on the BuiltTak bed. They have a slightly rough texture but it is much better than the one provided by tape. The company says that the surface should last for a while, I've done quite a few prints now and it seems to be holding up well.

Pro top: if you are printing lots of the same thing, move each one slightly on the print bed so that it spreads the wear on the surface. Also, if you want maximum quality, move the print closer to the back of the printer. This is because when the printer is moving at speed the print bed (which is only supported at one end) will tend to waggle and leave ripples in the printed surfaces.