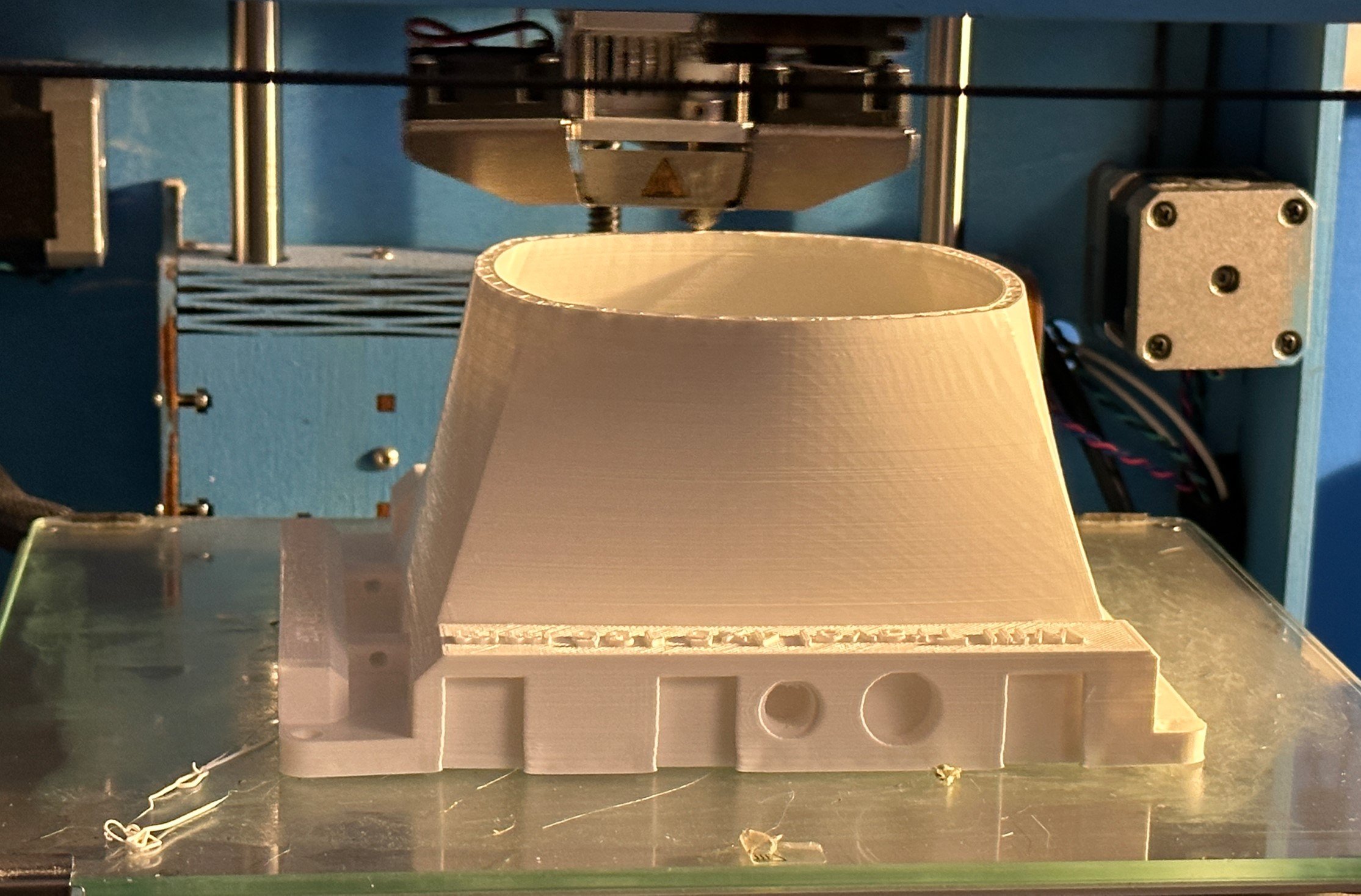

3D printed camera is now light - tight

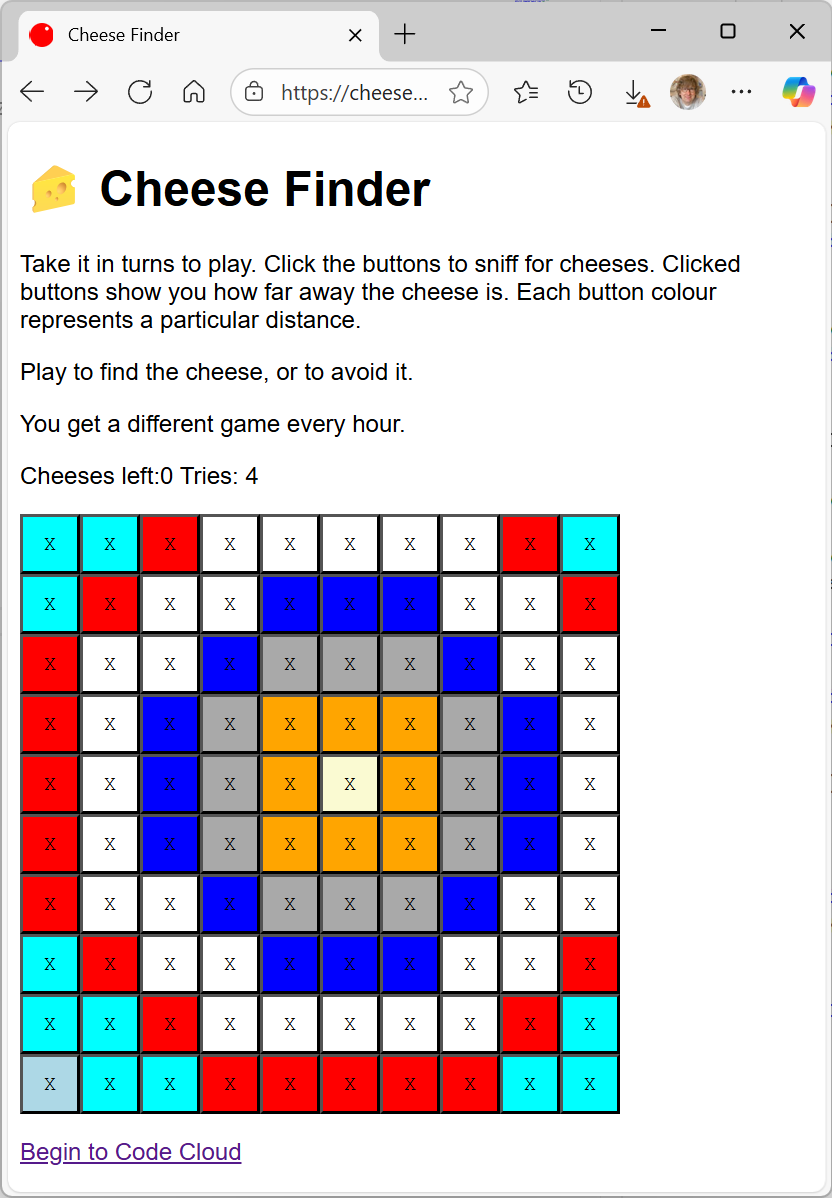

/I’m actually very happy with this picture

The picture above was taken using my 3D printed camera. The lack of any light on the image is actually very pleasing. While the film was in the camera I took it outside, shone torches and bright lights on it and generally waved it around in the brightest areas I could find. And the picture came out completely black. Which means I think that after a whole of of painting and masking it is now light tight.

I’m going to put a spirit level on the camera so I can tell when it is level…

I took the camera out for a walk and came back with this, which I’m quite happy with.