On Thursday, as we were building robots I came across one of the most amazing bugs I’d ever seen. We’d reached the point where the robots had been built and they were connected to the computer. My HullOS Editor program lets you write programs and send them into the robot for it to run them. But something weird was happening.

The editor was displaying things that it should not. It seemed to be duplicating program code that had been typed in. And nothing was working. It was very confusing. I thought back to the time I spent the day before testing the code and had to confess that I’d never seen anything like it before. In fact, if I’d set out to write a program that was doing what the editor seemed to be doing, I was not sure how I would do it.

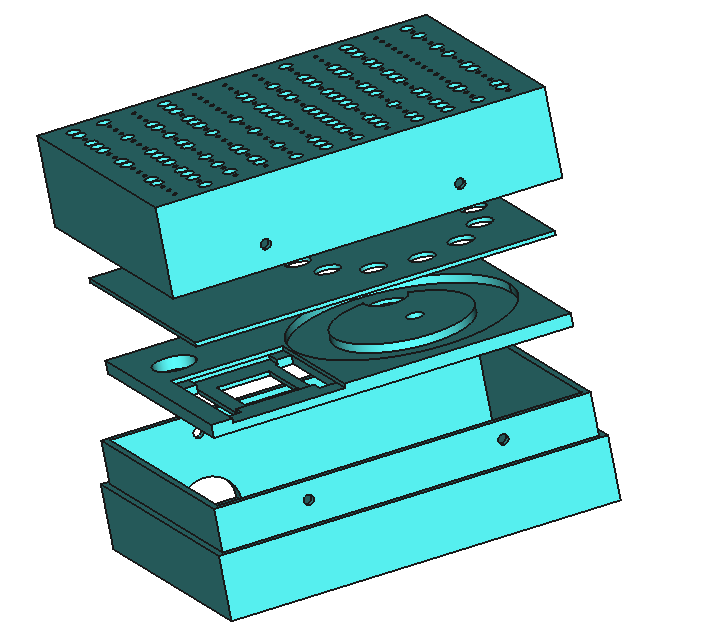

After a bit of head scratching I found the fault. And it wasn’t software. The robot has a speaker - more of a buzzer actually - which makes all kinds of irritating buzzing noises. Normally you’d connect a speaker across an output pin and a ground connection so that when the voltage on the pin goes up and down the speaker is driven in and out.

However, the Arduino doesn’t have many ground connections, and the ones it does have are all in use by the pixel and the distance sensor. So I use this rather clever (for me) trick of putting the loudspeaker across pins A0 and A1. If I make sure that A1 is always at the low logic level I can produce a potential difference between the pins by setting A0 high. This drives the speaker and sound comes out. I’m happy to trade a signal pin I don’t need for a ground connection.

This is probably deeply dodgy in electrical design terms. But since it works I think I have the last laugh on this one. Actually, if I had the time I’d experiment with swapping the ground level from one pin to the other while I play the waveform and seeing if this means I can make louder sounds by driving the speaker in and out, not just out.

Anyhoo, enough about my dodgy cleverness. Turns out that the fellow making the robot had wired his speaker incorrectly. Rather than wire the speaker between pins A0 and A1 he had wired the speaker between pins D0 and D1. These are two data pins on the Arduino which are also used for the serial port that is connected to the host PC. One of the pins is the data going into the Arduino and the other is the data coming out of the Arduino. Linking these pins together has the effect of sending every character that the PC sends to the robot right back to the PC again. Hence the terminal madness.

We put the speaker on the right pins and it worked a treat.

This illustrates one of things I said at the start of the robot building. Making robots is both fun and tricky because the combination of hardware and software makes for very “Interesting” misbehaviour.